"It's an 'industry disrupter.'" -Dan Mayer, Mayer Tree Service, Boston, MA

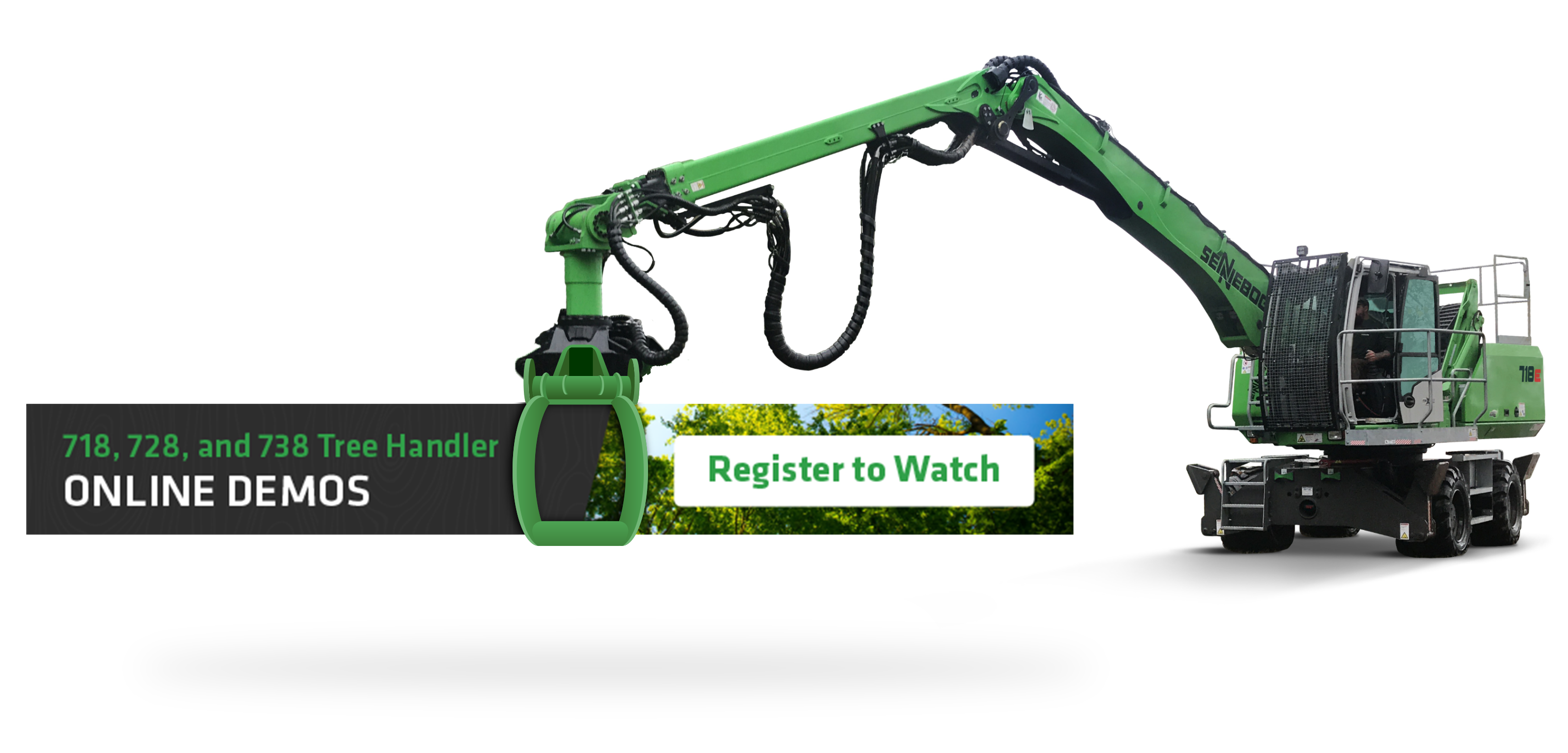

That’s how owners describe the SENNEBOGEN 718’s performance when it comes to tree removal. The revolutionary material handler was purpose-built specifically for the tree-care industry and is setting the pace for productivity and job-site safety in arboriculture.

Plenty of SENNEBOGEN machines are already used to increase efficiency in a variety of industries like scrap and steel, logging and forestry, and construction and demolition. But the role the 718 is playing in lightening the load of tree-care professionals is nothing short of stupendous.

Don’t just take our word for it. Meet a SENNEBOGEN customer who uses the 718 and learn how this type of machinery has fundamentally changed his business. We asked Jason Porter of Treeworks, Inc. in Michigan to share the challenges his tree-care company was facing and how the 718 solved those issues.

What Was Your Biggest Tree-Removal Challenge?

Jason has owned his tree-cutting business for 20 years. Before that, he did tree work with his dad. He knows a thing or two about trees.

Jason’s biggest challenge was duplicating aerial skills. He said it takes about six years to become an expert aerial tree worker. That’s a person who can go up in the bucket truck, do the climbing, and safely take the tree down. “Someone with that kind of experience is really hard to find,” he said.

Because skilled workers are sparse, Jason said keeping up with the work volume was a chore.

“It was always a full-throttle schedule trying to maintain that workload and maintain that expected schedule of when that work is supposed to be done,” he shared.

Over the years, Jason said, “the pressure of finding talent and meeting demand just kept building.”

How Did the SENNEBOGEN 718 Solve Your Problem?

Jason has kept track of what he’s been producing with the SENNEBOGEN 718. He said the tree-cutting machine is equal to two bucket trucks with a worker in each of them and two track loaders on the ground. That’s four machines and four crew members.

With the 718, Jason said he doesn’t have to search for more staff to add to his company because he or another employee can run the machine all alone. That saves him time and money.

“(I don’t have to) find that really secret, highly skilled guy who’s been doing tree work for six years,” he said.

“The 718 won’t take down every tree,” Jason said, “and a bucket truck and additional workers may be needed to take down a ‘monster,’ but in the end, the arbor machine will get most of the work done—and fast.”

“Let’s say there’s 50 trees that gotta come off of that job—roadside trees. I’ll be able to get 47 of them with the SENNEBOGEN.”

What Are Your Favorite Features of the SENNEBOGEN 718?

“I just like how powerful and precise it is."

“I just like how powerful and precise it is,” Jason said right off the bat.

The volume of material that’s able to be moved onsite safely and precisely by the SENNEBOGEN 718 continues to amaze Jason.

“I remember doing everything by hand. What I can accomplish now would take me two weeks. I can do it in like an hour,” he said. “The 718 is a rock-solid platform to work off of.”

“The telescoping boom is phenomenal. I don’t know any other machine similar that has that. The saw head is wonderful. It’s simple. It’s really strong. I love how you can change out the blades really quick for the different lengths of saw bars,” he said.

Perhaps Jason’s favorite feature of the 718 is that he gets to hop in the driver’s seat and get out in the field again. Performing his CEO duties gradually removed him from production over the years as he was building the company and completing administrative tasks that go along with being the boss.

“I wanna be relevant in being able to do tree work for another 20 years,” he said. “The SENNEBOGEN 718 allows me to do that.”

What Surprised You About the SENNEBOGEN 718?

At first, Jason didn’t think he needed an elevating cab. However, on a recent job, the feature allowed him to look down as he loaded heavy wood in dump trailers.

“Typically, if you’re in a track loader, you’re on ground level. You can’t actually see into the back of that truck. And when you’re lifting something really, really heavy with a track loader, if you accidentally drop it, you can damage your trailer,” he said.

Jason was also impressed with how solid the SENNEBOGEN 718 felt operating and rotating 360 degrees.

“I put those outriggers down and it feels like you’re just buried in cement. You are not going to tip that machine over if you get that thing properly set,” he said.

“Strength Under Control and Power”

The SENNEBOGEN 718 has been a game-changer for Jason because of the time he saves on projects and the money he doesn’t spend on additional staff and equipment.

Jason was having a hard time finding skilled aerial workers to go up in a bucket truck, climb a tree, and cut it down. Meanwhile, the workload kept piling up; the stress of it all was building, too. The 718 was able to alleviate the need for extra workers and accelerate the time it takes to do a job.

Plus, Jason just loves to run it.

You can read more stories from customers like Jason who use SENNEBOGEN machines and learn how the material handlers have improved their businesses on our website.

2023 Tree Care Workers’ Complete Guide to Machines & Equipment for Tree Removal, Urban Forestry, Storm Cleanup & More

Take an in-depth look at the SENNEBOGEN line of tree care handlers as we compare and contrast common equipment modifications to inform you on the best options for your tree service business.

Related: What It's Like to Operate a SENNEBOGEN 718 Tree Handler