When it comes to material handlers for ports, diesel is the standard. But, is it the best choice? Not always. Yes, diesel is a cheap fuel, but this should not be your only consideration in choosing the power source for your material handler. You have to consider a host of other matters before making a decision.

First is maintenance. Diesel material handlers operate on hydraulics, which need frequent and expensive maintenance. You don't get that with electric material handlers. They require very little maintenance. The truth is that the electric models are more expensive up front. However, they are cheaper to own over time than diesel machines.

With electric models, you have less energy usage costs, and lower maintenance expenses. Most electric material handlers pay for themselves in a year or two. With diesel machines, their initial cheap cost gradually increases over a year or two to actually cost more than the electric model.

Because of this, Sennebogen is a big fan of electric material handlers, and we encourage our customers to consider them for their ports. While diesel is the industry standard, there are many important benefits to electric that you should not ignore. We are happy to give you any information you need on electric material handlers, so you can make an informed and correct decision for your port.

Advantages of Electric Material Handlers

You Don't Have to Stop Work to Re-Fill the Diesel--

With diesel machines, the tank will run empty every eight hours of operation or so. It can take 20 to 30 minutes to re-fill the tank. This is lost productivity time, when your port could be getting more done, rather than waiting around for the diesel machine t be re-filled. And, of course, lost productivity time means reduced profits over time. You can be more productive and maintain or increase your profits with an electric material handler.

Your Maintenance Costs are Lower--

Diesel machines require much maintenance. Not only do you need to keep them supplied with engine oil and change their filters on a periodic basis, you have to keep the hydraulics in good operating order with regular maintenance. Any maintenance results in downtime on the job, which is bad for business, as we've already established.

Electric material handlers do not require fuel, oil, or filter changes, and while you have to do maintenance on the hydraulics every 250-500 operating hours on a diesel machine, it's only every 2,000 operating hours on an electric machine. The benefits here are clear and obvious.

The Hydraulics Last Much Longer on an Electric Machine--

Diesel machines generate more heat than electric ones, and also vibrate quite a bit, whereas electric machines have smooth operations. The heat of a diesel machine can damage the hydraulics, while the vibrating can wear out the hydraulics quickly.

You don't have these issues with an electric machine, so your machine lasts much longer. You may go through two or three diesel machines (or replacements of their hydraulics) or more before you would have to consider replacing an electric one or electric machine hydraulics.

Electric Material Handlers Don't Overheat or Freeze on Their Motors--

This is because they are not water cooled, which diesel machines are. With a diesel machine, the motor can overheat if there is not enough water in the radiator, and the water can freeze if it gets really cold outside. This results in loss of productivity and loss of profits. Because there is no water involved with an electric machine, you don't have these issues, and can keep working in any weather.

Watch our Video on the differences here!

Are There Disadvantages to Electric Material Handlers?

The only thing that might be considered a disadvantage with an electric material handler is that you must have a cable attached to the machine to give it energy; this limits the area in which it can move, as it can only move as far as the cable will allow it.

You can work around this issue by having power stations around your port where the machine can be unplugged, then plugged in again in a more advantageous place, if it needs to move beyond its original operating radius. If your port is small and your material handler doesn't have to go very far, then this isn't an issue for you at all.

When you add the fact that using an electric material handler is more environmentally friendly than a diesel one, and that can give you the advantage of feeling good about helping make the planet a better place, the choice to use electric material handlers is a clear one for most ports.

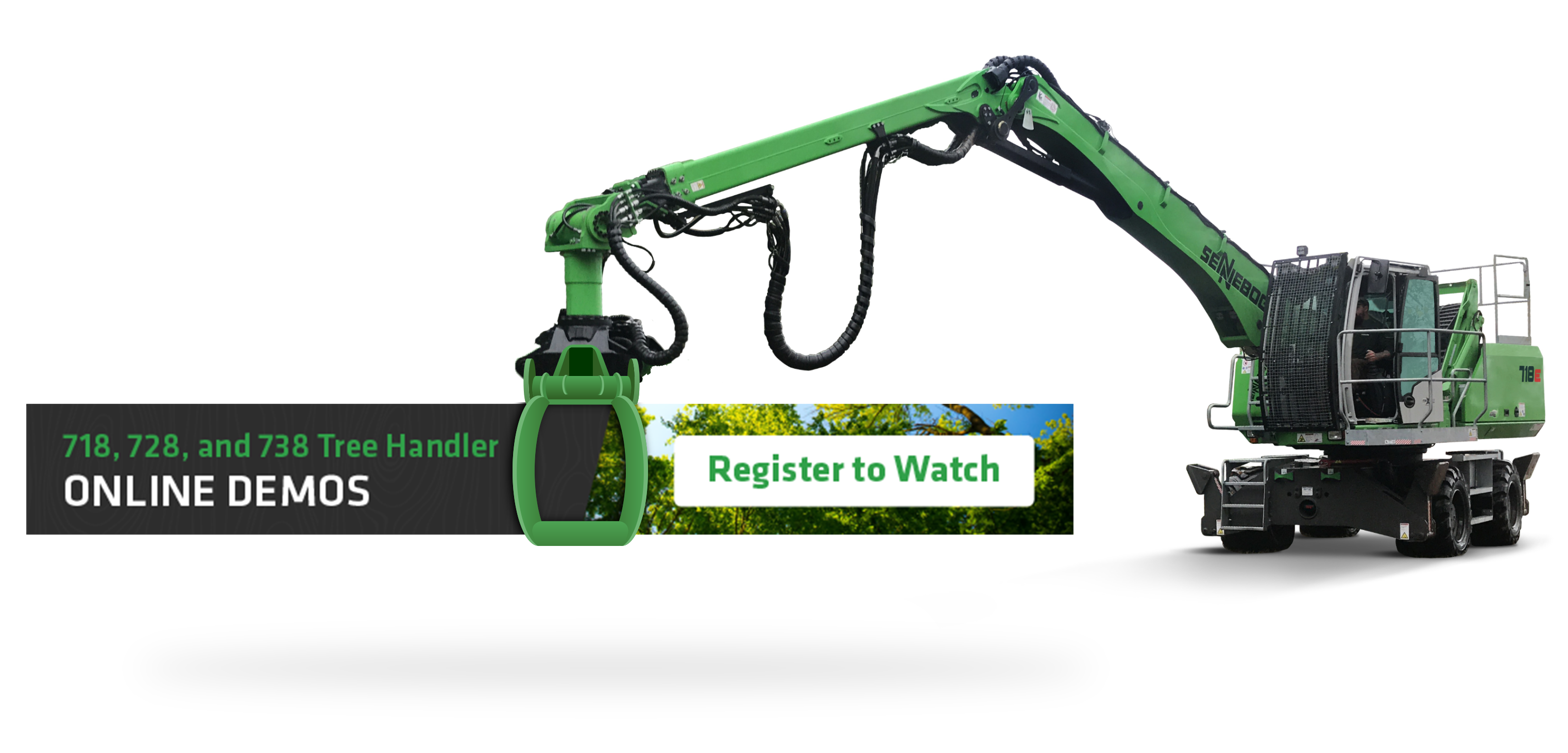

Take an in-depth look at the SENNEBOGEN line of tree care handlers as we compare and contrast common equipment modifications to inform you on the best options for your tree service business.

.jpg?width=512&height=399&name=unnamed%20(94).jpg)