In the life of a tree-care professional, the work is never truly done.

There’s always another job waiting around the bend. The quicker workers can complete a project, the faster they can tackle the next one. That means more money is being brought into the business.

This makes equipment efficiency of the utmost importance. You need tools and devices that will save you time and produce quality results. Good use of your crew’s time and energy will ramp up your productivity and increase profits.

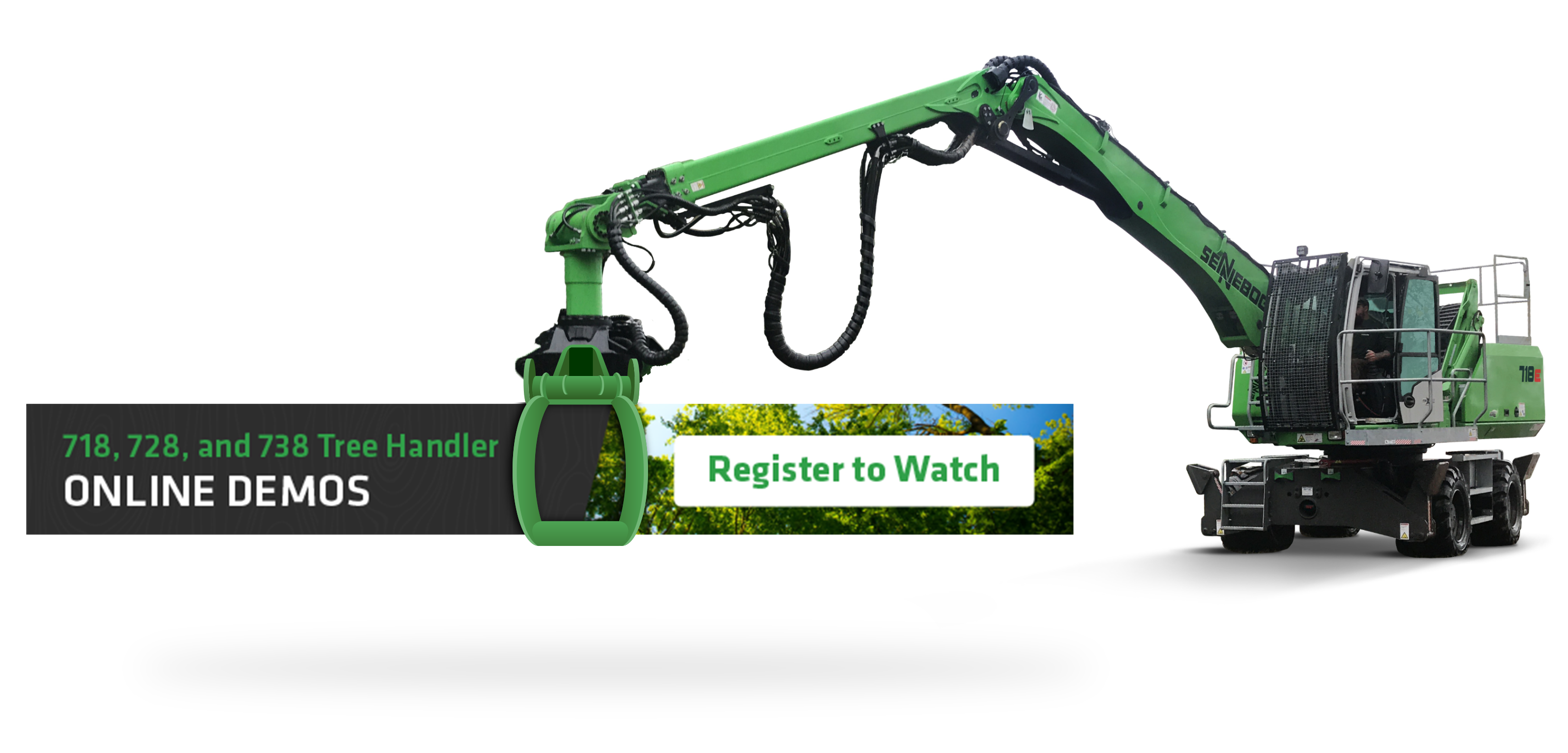

The SENNEBOGEN 718 eliminates many of the elements that slow down work at a tree-removal site. From equipment to service to mobility, this material handler literally cuts out the middleman and puts your crew on the fast track to the next job.

Traditional Tree Removal Practices

In traditional tree removal, you have to set up a lot of rigging equipment to prepare to climb a large tree. Friction brakes, rigging plates, and carabiners are a few of the necessary tools—plus lots and lots (and lots) of rope.

In traditional tree removal, you have to set up a lot of rigging equipment to prepare to climb a large tree. Friction brakes, rigging plates, and carabiners are a few of the necessary tools—plus lots and lots (and lots) of rope.

You need more equipment to actually climb the tree. Protective clothing, straps, and spurs are some of the staples, as well as a first-aid kit you hope you never have to use. A majority of equipment you’ll find in a tree-care professional’s arsenal is geared toward climbing.

Finally, there are the tools you need to cut down the tree. Polesaws, pruners, and tree loppers are some of the equipment needed—along with the almighty chainsaw. Equipment used for trimming trees includes saw scabbards, hydraulic tools, and landscaping tools.

Traditional tree removal requires plenty of rigging, climbing, cutting, and trimming equipment, as well as a team of workers to bring large trees and limbs safely to the ground. Once the job is done, the crew must transport all of those tools and heavy tree removal equipment to the next site.

Time-Consuming Processes

As you can imagine, there’s a long list of tasks that need to be done before the cutting of a tree can begin. And these things take time.

It takes time to set up all of the rigging equipment so a worker can climb the tree. There are additional moments spent adjusting that equipment when the worker needs to move around.

It takes time for the worker to move the climbing, cutting, and trimming equipment around to various areas of the tree. Plus, all of that equipment must be moved from site to site as each job is finished.

It takes time to get multiple team members in place around the worksite to complete the project from start to finish. Proper precautions must be taken to make sure they’re all safe and out of harm’s way.

Additionally, it takes time to service the rigging, climbing, cutting, and trimming equipment. Since there are so many tools to keep track of and maintain, repairs are time-consuming.

The SENNEBOGEN 718 Way

No Need for Any Rigging

With the SENNEBOGEN 718, there’s no rigging equipment to set up or adjust because the worker doesn’t climb the tree. Everything is done from the cab with the telescopic boom, grab saw, and other attachments.

- The telescoping stick adds precision and control with a total horizontal reach up to 43 ft (13 m) and a vertical reach up to 45 ft (13.7 m)

- Interchangeable saws, grapples for multiple tree care applications

Transporting Equipment Is Easy

The crew no longer has to transport equipment piece by piece. The SENNEBOGEN 718 is mobile, so the worker can drive it around the site (as well as from job to job).

- Compact size allows efficient maneuvering in tight, urban worksites

- Easy to transport without special permits

Only One Operator Needed

The crew of a SENNEBOGEN 718 is whittled down to one. There’s only one worker needed in the cab. That means it takes fewer people to do the job—and there’s no need to wait until everyone is out of harm’s way.

- High-reach boom and stick can quickly switch between a full range of grapple saws and attachments to complete all tree-care applications with one machine and one operator

- Fully enclosed, elevated cab provides protection for operators and a wide-angle view of the work zone and the complete job site

Service Is a Snap

There’s virtually one location for all the servicing the SENNEBOGEN 718 needs—and it’s at ground level. All the fuses and relays are grouped together in a centrally located box for easy access.

- With hydraulic controls instead of electronics, the 718 requires no special software or “black box” components to troubleshoot your machine

- Solid steel top-opening compartment doors on the sides and top of the upper deck maintain a secure fit, even after repeated opening for service

Agile Cutting and Loading

Now you know why overall equipment efficiency is important for tree removal.

The more time spent preparing for and completing one job, the more money lost on another opportunity. The SENNEBOGEN 718 is renowned as the industry leader in preventing downtime and protecting people.

The 718 is designed for responsive, agile cutting and loading. It reduces operational costs for energy, workforce, and service parts. On average, the machine can cut and stack six trees per hour.

When you purchase a SENNEBOGEN, you’ll know it was purpose-built for you from the ground up. Check it out for yourself! Watch this virtual demonstration of the 718 in action.